As a result of technological advancement, this explains why CNC Milling Services centers can perform complex milling operations that allow businesses to produce more functional components. However, if you own a business with some older CNC machining centers, you may have problems adjusting to a newer version or keeping the older one.

The Size of Your Manufactured Components

For example, if your business requires machines that can ideally produce large or small components, you need a giant milling machine to produce massive parts and, conversely, a remote machine. On the other hand, if the size of the elements does not change, you may not need to change your outdated CNC machining centers.

The Complexity of the Component Layout

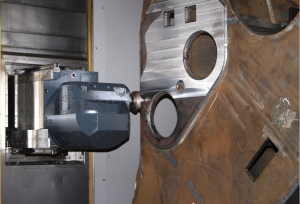

Newer models tend to have their distinctive assortment of axes, reflecting the simultaneous movement of the main tools, such as 4- and 5-axis machines. If you are likely to perform positioning work on multiple complex parts over a long period, you need advanced machining centers to perform complicated manufacturing operations.

On the other hand, if your company only requires 3-axis CNC milling machines, it means you can only produce parts with a lower degree of difficulty. CNC milling machines are available in many different styles. If you consider purchasing a high-quality system, make sure the dealer offers service solutions to help maintain and repair the device in the early stages until someone in the company can learn how to do it. In addition, reputable dealers can offer rebuilds of older CNC milling machines. It is also an economical alternative to buying new.

The Current Form of the Used Machine

When existing machining centers are sent in for maintenance, there are high long-term maintenance costs to contend with. In terms of a scenario where it pays to buy CNC milling machines rather than pay for care, it makes sense to consider purchasing new variants to replace your existing devices.

A second-hand grinding machine or machining equipment can be inexpensive and include some support and warranty packages if bought from the perfect dealer. In the case of these machines, it is tempting to opt for a cheaper, used version because of the higher costs a company may incur, but it may not be best. When buying a machine, ensure that there is some warranty and that the engine was picked up while in service

The Difficulty of Accuracy

Suppose your CNC milling machines have accuracy issues, for example. In that case, if the components manufactured are far from the precision series, this will affect the standard of the parts, and you will have customer complaints. Newer versions have integrated and updated control software that could speed up more complex and higher precision grinding operations. However, should you experience productivity problems with your older machining equipment, this will affect your turnaround time and long-term position.

The Cost of Cleaning the Equipment

The broader versions have effective chip control to keep chips out and internal cutting tools clean. If you don’t have a problem with cleaning costs, stick with the old CNC milling machines and do your milling work as usual. However, I hope you can make a wise decision to buy a new CNC milling machine by considering several points mentioned above. If you think you don’t need to buy machining equipment, why not try outsourcing your CNC milling work now? Unfortunately, finding companies that offer quality and affordable CNC milling services can be a time-consuming process.